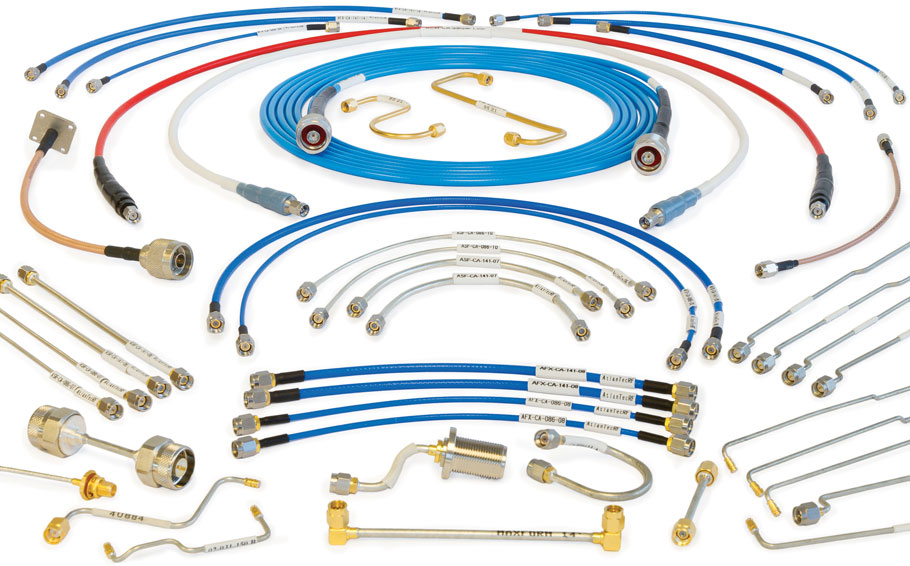

Atlantic Microwave offers a wide range of cable assemblies to meet many different applications. This article provides guidance towards the correct choice of cable assembly by describing the product range, its features and its benefits.

Test Cables

The principal requirements of a test cable are durability, stability during flexure and overall electrical performance. The CA18 series of test cables comprises three types, all of which exhibit these features:

ARC (red jacket) | for general purpose test applications |

All three types have durability features in common such as high connector retention and multilayer bonded strain-relief boots. Only high-quality stainless steel connectors are used and the jackets are colour-coded to help with identification. The ARC and ACW cables employ FEP (Fluorinated Ethylene Propylene) as the outer jacket. This material offers high resistance to abrasion and wide operating temperature range (typically -55 to +105 °C) but it is stiffer than the polyurethane used in the ultra-flexible type ABC product.

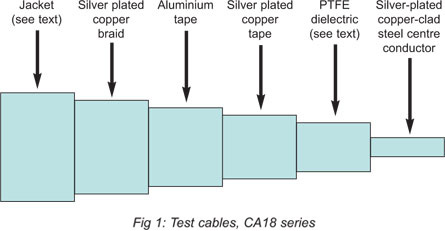

The internal construction of all three cables (Fig 1) comprises a solid centre conductor (for lowest loss) and three layers of screening over a PTFE dielectric. These three layers comprise two layers of spirally-wound silver plated metal tape under a silver-plated copper braid. These provide high electrical screening together with good phase stability under flexure by minimising dimensional change.

It is helpful to understand what happens when a cable is flexed. When a cable is bent, the inside circumference of the bend is smaller than the outside circumference. This places stress on the dielectric and the outer screen and can lead to an impedance change and a change in electrical length manifest as a phase change. The use of intermediate spirally-wrapped screens which can slide over each other minimises this effect and these cables typically exhibit less than +/- 2 degrees phase change with flexure.

The general purpose and ultra-flexible cables employ solid PTFE as the dielectric whereas the low-loss cable uses low-density PTFE which has a lower loss tangent. This latter material contributes to an exceptionally low insertion loss of 1.35 dB/m at 18 GHz.

All these cables operate up to 18 GHz and are available from stock in standard lengths with either male SMA or Type N connectors. Custom versions are available to order, including non-standard lengths, different connectors, custom labelling and armoured jackets. Test data and phase-matching can also be provided. Raw cable and loose connectors are available, although for optimum performance it is always preferable to have the manufacturer attach the connectors.

Flexible Cables

The AFX series of cable assemblies is a range of 0.141 and 0.086 diameter cables stocked in a choice of lengths and fitted with male SMA connectors as standard. These cables are ideal for general interconnection purposes such as joining sub-assemblies within a chassis or interconnecting panels in a rack of equipment. Because of their smaller diameter they have more loss than the test cables described above but they are highly flexible, which makes them easy to handle in confined spaces. In view of the intended applications, loss is not usually an issue as most lengths are fairly short.

These cables have a two-layer outer screen (Fig 2) so they are not as phase-stable as the test cables but, once installed, they are not normally subject to flexing. Where flexing occurs and stability is important, the test cable range is recommended.

The cable assemblies can be supplied to order with different connectors such as right angle and bulkhead SMA, Type N, SMP etc. In particular, AtlanTecRF supplies a low-profile right-angle male SMA which is ideal for applications which are tight for space.

Reformable Cables

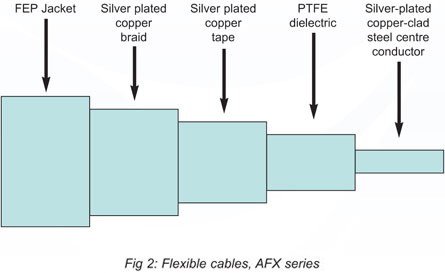

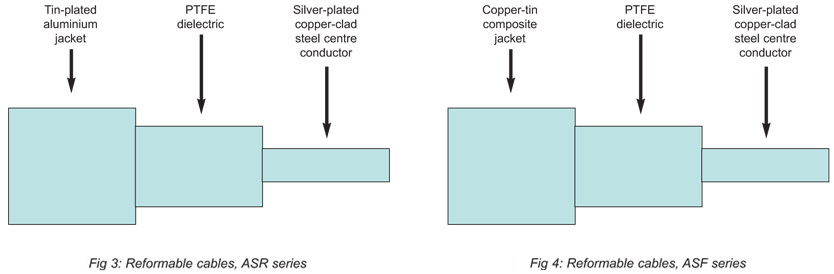

Reformable cables are sometimes described as semi-rigid and semiflexible. Atlantic Microwave's reformable cable assemblies fall into two categories according to the type of outer screen used. One type, known as the ASR range, has a tin-plated soft aluminium outer (Fig 3). The other, ASF, range has a copper-tin composite braid as the outer screen (Fig 4). Both are stocked in a range of standard lengths.

The ASR range offers essentially the same performance as traditional copper semi-rigid cable of similar size (0.141 and 0.086 in) but with the feature of being easily hand-formable thus saving the designer the trouble of specifying the precise and possibly complex design of a custom semi-rigid cable which may then take considerable time to manufacture. Also, because the cables can be formed in-situ, difficult fitting situations can be avoided. The cable comprises a silver-plated copper-clad steel centre conductor, PTFE dielectric and a soft aluminium outer jacket which is tin-plated. The SMA male connectors which are fitted as standard in the stock assemblies have anti-torque nuts to help protect the cable from damage by twisting during mounting. These cable assemblies offer all the benefits of custom made semi-rigid cables without the drawback of design and manufacturing time. They can be reformed many times before the onset of work-hardening.

The ASF range has similar internal construction as the ASR range but the outer conductor is a copper-tin composite braid. This offers the benefit of high formability with zero spring-back and electrical performance which approaches that of copper semi-rigid. There is a marginal (approximately 10% of dB value) increase in insertion loss which only becomes significant in long lengths (eg 0.1 dB in a 450 mm length at 18 GHz) and 10 dB lower shielding ratio. Being softer than the equivalent ASR-type it can be bound into cable looms and harnesses and easily threaded through holes and around obstructions.

The ASF range has similar internal construction as the ASR range but the outer conductor is a copper-tin composite braid. This offers the benefit of high formability with zero spring-back and electrical performance which approaches that of copper semi-rigid. There is a marginal (approximately 10% of dB value) increase in insertion loss which only becomes significant in long lengths (eg 0.1 dB in a 450 mm length at 18 GHz) and 10 dB lower shielding ratio. Being softer than the equivalent ASR-type it can be bound into cable looms and harnesses and easily threaded through holes and around obstructions.

AtlanTecRF supplies the model ATW-S01SMA torque wrench for use with the SMA connectors used on its cable assemblies. This wrench is preset to the correct torque and calibrated in accordance with MILSTD-45662.

Conclusion

AtlanTecRF offers a wide range of flexible and reformable cable assemblies from stock to suit many applications including test, module interconnection and equipment installation. The range of stocked products is increasing as customers recognise the convenience of off-the-shelf delivery. Furthermore, many custom features can be supplied to order to meet individual requirements.